LASERSTOP LOOM 4082

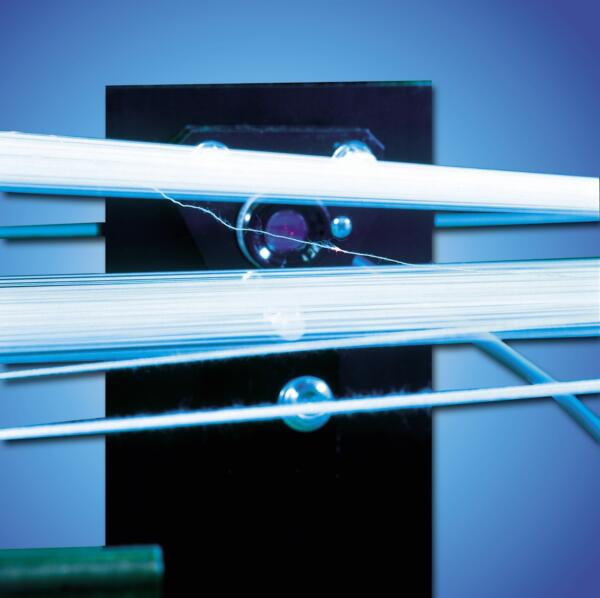

Thread Break Detector for Weaving Machines

The thread surveillance device LASERSTOP LOOM 4082 impresses through its high quality and an outstanding price-performance ratio. The system recognizes a wide range of faults in yarn thickness as low as 12 dtex during the Weaving process. An immediate stoppage of the Weaving machine will occur even where the usual dropper systems fail.

- Reliable and fast fault detection

- Light barriers using innovative laser technology

- Easy operation

Features

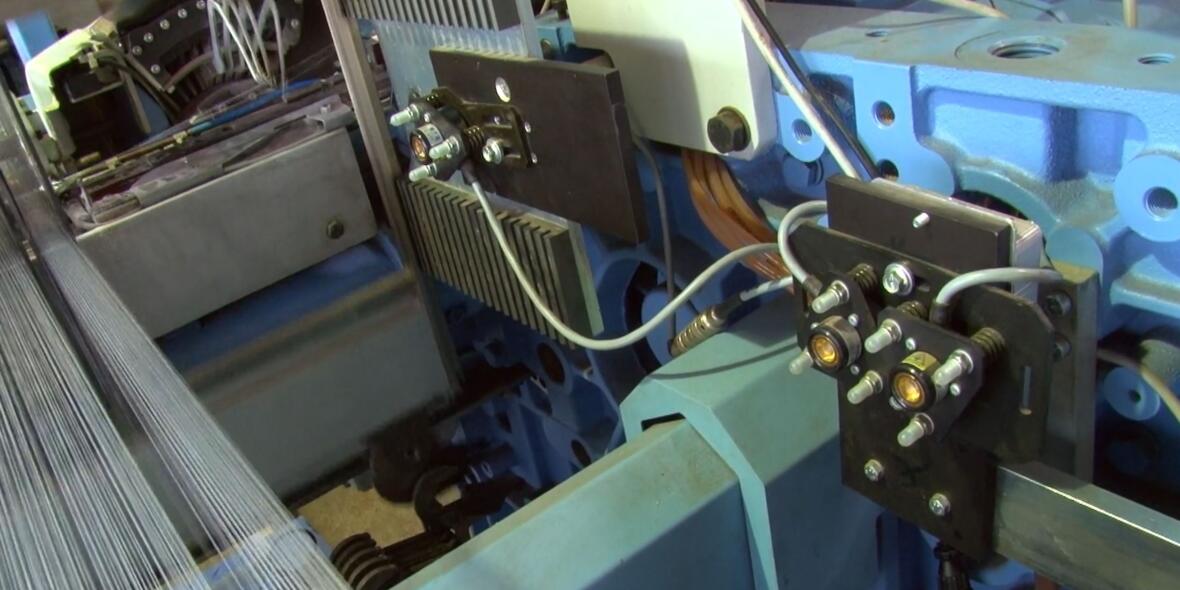

Positions for fault detection

- Clamping threads or nests in the rear-shed or front-shed position

- Thread breaks at the yarn sheet run-in

Reliable fault detection

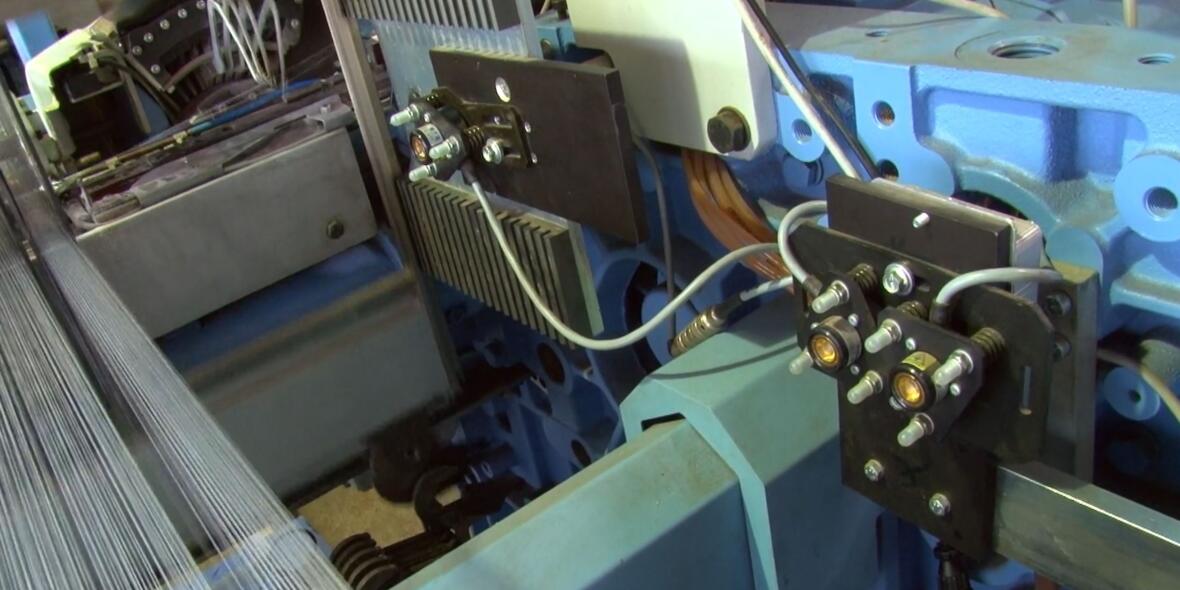

- Continuous and automatic surveillance with digital signal evaluation

- Automatic adaptation of the system to the machine speed

- High sensitivity and vibration independence

- Colour coded LED display of the light barrier’s operational condition for fast fault location

- Clearly noticeable external signal lamp to indicate stops

Maximum productivity

- Fast reaction time minimizes fault lengths

- Immediate and reliable machine stoppage even at high speeds

- Channel 2 with selectable DuoSplit function to reduce false stops caused by dust

No material or yarn abrasion

- Contact-free control preserve both yarn and woven fabric

- Minimal maintenance and service effort for an economic production

Ease of use

- Separation of the control unit and LCD hand terminal ensures operational security, user comfort and reduces costs

- Simplified setting procedure avoids input errors and minimizes preparation time

Product tour

Technical data

Downloads (2)

Accessories (1)

| Description | Value |

|---|---|

| Max. connection: | 2 laser light barriers |

| Laser class: | 1 |

Product brochure

Questions?

Submit your data and you will be contacted by one of our experts