The only comprehensive system for automated surveillance of Tufting machines

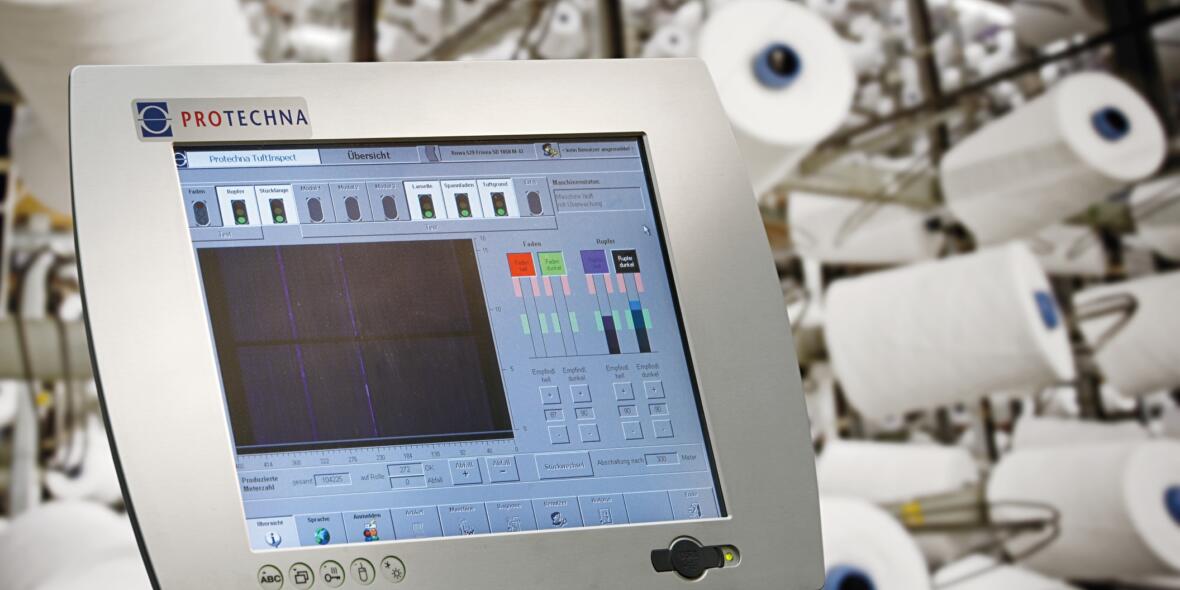

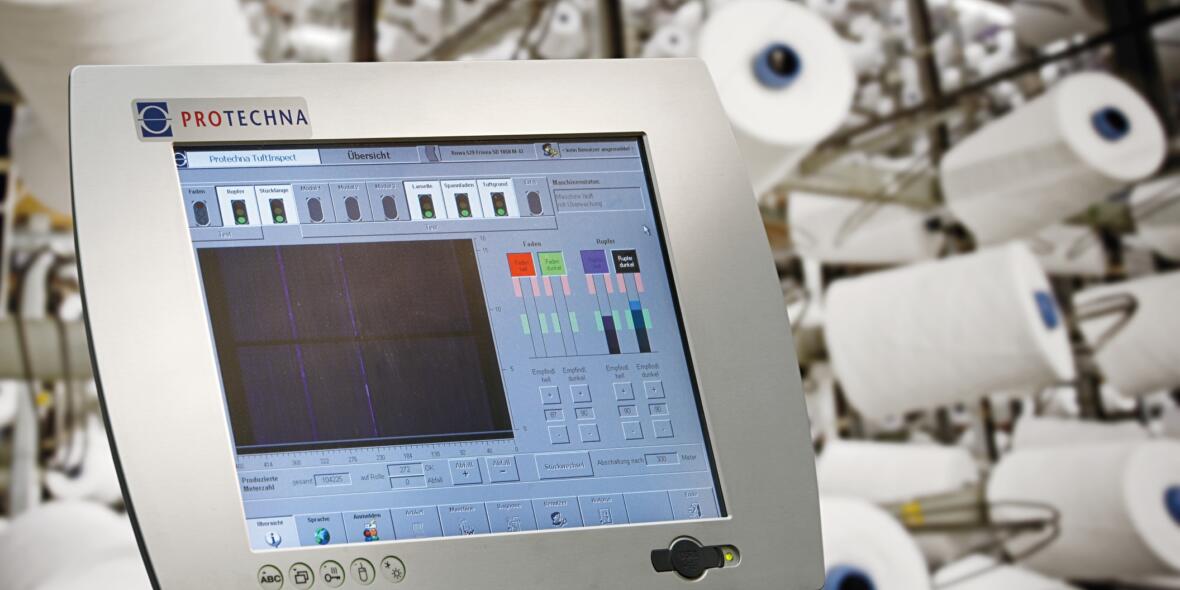

TUFTCAM 5320 is established as a robust and inexpensive camera system, suitable for industrial use on wide width fabrics and has been developed and adapted to meet the special needs for Tufting. It is suitable for monitoring machines producing cut pile as well as loop-pile carpets.

- Comprehensive system which allows to operate the machines without supervision

- Easy operation using a durable touch-screen

Features

Stay in control

TUFTCAM 5320 checks the raw carpet just a few stitches after the needles. The machine stops automatically as soon as a fault occurs. A flashing light alerts the operator and the large dot matrix display indicates the fault position. The current fault type is shown on the graphical user display and is stored in the electronic production protocol.

Easy operation

TUFTCAM 5320 displays the current signal for the raw carpet during the normal operation of the monitoring device. This makes it possible to set the optimal machine stop switching level for any produced article. These values can be stored. If the width of the article is altered, the required monitoring area can be set accordingly (also with separating gap). The adjustable reaction time setting can optimise the fault recognition for a fault length as short as possible.

3 excellent TUFTCAM advantages, which make it worthwhile

TUFTCAM 5320...

- allows a flexible and efficient round-the-clock production and opens the door to multiple machine operation by only one person.

- supports you to increase the quality of your production by avoiding faults or reducing substantially their length and consequences.

- creates a fault protocol by an objective measuring, which serves as a certificate for customers and suppliers.

Fault detection

Missing thread

TUFTCAM 5320 detects the missing row of tufts in the carpet after a thread

break has occurred. The thread break can sometimes be recognised by

TUFTCAM 5320 even before the thread end has run out of the needle due to the

reduced thread tension.

Double threads

Stop of the machine, when a thread has jumped into a neighbouring needle.

Needle deviations

An adjustable sensitivity makes it possible to recognise needles that

are out of alignment. TUFTCAM 5320 can learn an accepted needle image and

only deviations from this image will lead to a machine stop. Therefore,

the visual inspection will still work, when the machine is not perfectly

adjusted.

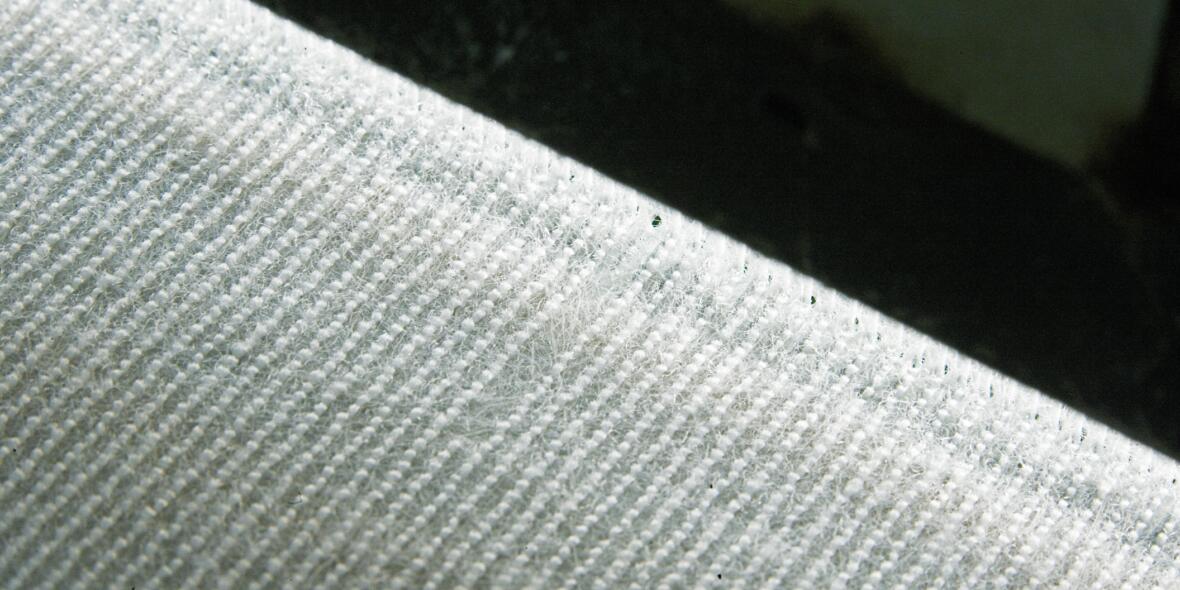

Pull-down and plucking at cut pile

The control for pull-downs, caused by wear or damage of the cutting blades, is carried out on the back of the raw carpet.

Stopping at end of primary backing

An additional sensor prevents primary backing from running empty.

Piece length and repair stop

TUFTCAM 5320 stops also automatically the take-up unit when the predefined

piece length or the position for repairing a fault is reached.

Product tour

Product brochure

Submit your data and you will be contacted by one of our experts